Technical Information

The Three Wire Method Of Measuring Pitch Diameter of Straight Threads

In regards to the origins of the Three Wire Thread Measuring method, the following is an excerpt from FED-STD-H28 (1957) Pt. 1. "The accurate measurement of pitch diameter of a thread, which may be perfect as to form and lead, presents certain difficulties which result in some uncertainty as to its true value. The adoption of a standard uniform practice in making such measurements is, therefore, desirable in order to reduce such uncertainty of measurement to a minimum. The so-called "three–wire method" of measuring pitch diameter, as here outlined, has been found to be the most generally satisfactory method when properly carried out, and is recommended for universal use in the direct measurement of thread plug and thread setting plug gages."

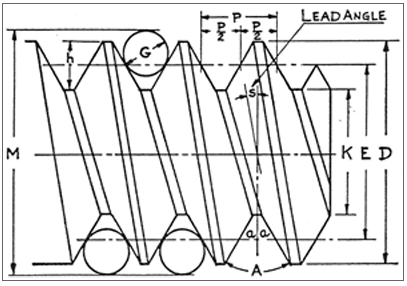

Screw Thread Elements

Important definitions and formulas:

- FLANK ANGLE (or HALF ANGLE) – This is the angle formed by a contacting line tangent to the actual flank profile and a plane perpendicular to the thread axis. On a symmetric thread it is represented by the Greek letter alpha (α). On an asymmetric thread the flank angles are represented by α1 and α2

- THREAD ANGLE (or INCLUDED ANGLE)- This is the angle formed by two adjacent flanks in an axial plane. On a symmetric thread it is represented by 2α . The angle of thread is known from the name of the thread. All Unified form and National threads have a 60° included angle. Acme and Stub Acme threads have a 29° included angle, and Whitworth threads have a 55° included angle. American Buttress, British Buttress and MJB (metric buttress) threads have a 52º asymmetric thread with 7º and 45º flank angles. The included angle is represented by α1 + α2.

Need Your Thread Gages, Rings or Plugs Calibrated?

Address

Thread Gage Calibration

Osborn Products

1127 West Melinda Avenue

Phoenix, AZ 85027

Email Us